Silkscreen printing, also known as screen printing, is a popular method for applying designs on apparel such as t-shirts and polo tees. Silkscreen printing is the widely preferred method for printing high quantity orders. As silkscreen printing is done in a way that allows the ink to bond with the fibres of fabric, the print is highly durable and does not peel off easily.

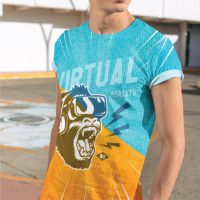

Sublimation printing method is used mostly for creating customised jerseys and tees, this technique allows for full coloured prints all over the fabric. The colour is permanently absorbed, which means it won’t flake off, and gives the fabric a fantastic soft feel.

On top of that, sublimation printing allows you to choose from an almost unlimited colour palette, creating brighter and smoother colour variations. Sublimation printing uses heat sensitive inks that turn into gas under the influence of heat and infuse directly into a 100% polyester fabric.

Our heat transfer printing produces a high-quality result, with smooth graphics and excellent image resolution. Our heat transfer material comes with our full quality assurance.

Choose from a wide range of colours and finishes for your prints, including matt, metallic and 3M Scotchlite Reflective Vinyls.

We offer high quality Yupoong Flexfit caps for our customers to print their logos or text on. There are many cap styles available for customisation, such as a 5 panels trucker cap or the classic 6 panels snapback cap. The front panels of a cap provides the perfect, highly visible space for a corporate logo or slogan.

Prints can be done on various positions of a cap such as the front panels, side panels and the back. For ready stock caps, the printing method can either be Heat Press Printing or Silkscreen Transfer printing.