What is Silkscreen Printing?

Silkscreen printing is also known as screen printing. In the past, screen meshes were made of silk, however screens are now commonly made of polyester or nylon. The finer the mesh, the better it can print artwork made of finer details. The silkscreen printing method uses a piece of mesh to transfer ink unto different surfaces, akin to how a stencil method works. Colours are printed individually, layer by layer. For example, blue layer first before the green layer. Silkscreen printing produces bright, vibrant print colours.

Artwork Creation for Silkscreen Printing

The first part of the silkscreen printing process is the logo or artwork creation. We recommend working in the program, Adobe Illustrator to create a vector file for it to be print ready. This makes it easier for editing. While creating the artwork, be sure to keep in mind to keep the layering as clear cut as possible. For example, the shade of light blue should be on 1 layer, while the shade of green should be on another layer. Apart from working with clear layers, remember to keep your artwork tidy. Remove all details which are not desired in the final print outcome.

One tip is to use the Pathfinder tool in Adobe Illustrator. We suggest merging separate shapes, which happen to touch one another, into 1 big shape. An additional tip is to make sure all strokes are outlined. This is to prevent the thickness of the strokes from changing when the artwork is resized.

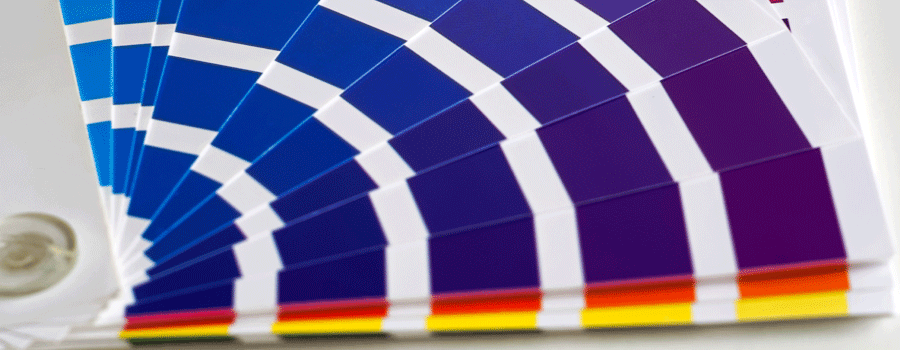

Work with colours in reference to a physical Pantone Matching System (PMS) Solid Coated colour reference book. All monitors and screens have different colour calibration settings. The red colour on one screen, will look darker or lighter on another screen.

Simply searching the Internet for a graphic image and saving it with the intention of printing the image on apparel is not recommended. A big issue is copyright and most times, the image quality of the graphic image is not ideal for it to be directly translated to silkscreen print. A graphic designer will need to trace out the image in vector format so that the resolution is high enough.

However, some customers may have only a small resolution image of their own logo or artwork. Our design team is able to trace it out and get it ready for print processes.

Silkscreen printing inks

Silkscreen printing is not limited to the commonly used plastisol ink only. There are different types of inks available for different visual effects. Depending on ink type, sometimes an under layer of white is printed first to ensure the end result of colour is vibrant and rich.

1. Discharge inks

Used on dark coloured fabrics, the discharge ink creates a chemical reaction with the dye and removes the dye of the fabrics.

2. Puff inks

Adding puff inks to plastisol inks will create a raised print.

3. Flock silkscreen print

Flock material which feels like suede or velvet, is added with glue unto the fabric.

4. Metallic or glitter silkscreen print

Glitter flakes is added to the plastisol ink to create a shiny look.

5. High density silkscreen print

For solid graphic elements, the high density silkscreen print method can raise the print to about 3mm height.

6. Gel inks

These inks produce clear and transparent high density print effects.

7. Glow-in-the-dark prints

The prints will have a green tone and is usually printed on a white or light coloured base.

Factors that affect cost of Silkscreen Printing

- Artwork preparation/Colour Separation

- Quantity of order

- Type of apparel

- Type of ink

- Size of print

- Number of colours

- Number of positions per apparel