Heat press printing is also known as heat transfer printing. It is a print process of applying heat and pressure to a print material onto fabrics or apparel. The print material has an adhesive side which reacts to heat. When the heat press machine is activated, it will press the print material down with high pressure, allowing the adhesive side to bond with the fabric in a few seconds. Heat press printing is commonly used for t-shirt printing as it is good for smaller quantities. Heat press printing is also favoured due to the versatility of print positions. Heat press printing allows solid colours or full colour, gradient colours to be done on apparel.

There are 2 types of heat press print materials. One material is the single colour vinyl and the other material is the digital print vinyl. For the 1 colour vinyl material, the selection of colours is limited to solid colours and metallic colours.

For digital print vinyl, full colour logos and artwork can be printed. Details such as gradients and fine lines will be able to be printed out on the vinyl before the vinyl is heat pressed unto the fabric.

All vinyls come with an underlying plastic sheet to protect the vinyl’s adhesive side.

Single Colour Vinyls

Desired shapes are plotted out, or in other words, cut out from a large roll of vinyl material for t-shirt printing.The maximum width of the vinyl material which can be plotted on, is 46cm and is usually about 25 meters long. However is not recommended to set the plotting machine to cut shapes out for a long distance at any one time. The shapes may be skewed due to the rolling of vinyl by the plotting machine.

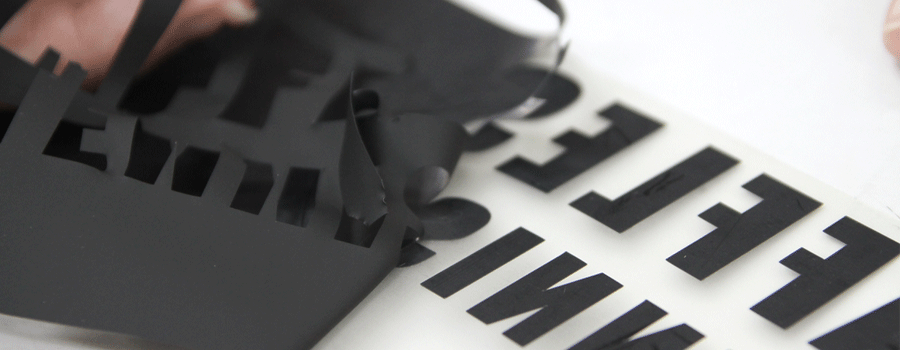

If you have an artwork or logo with 2-3 solid colours, it is possible to print the artwork using the single colour vinyls. The artwork has to be separated into layers, 1 layer for each colour. The plotter will cut shapes out of 1 colour of vinyl at any one time. Once all the required shapes have been cut out, the weeding process starts. Weeding involves removing vinyl material from the shapes that were cut by the plotter, such as the counters of alphabets or the negative of illustrations.

The different shapes of various colours will be pieced together to form the entire artwork or logo before being heat pressed unto apparel such as t-shirts and polo shirts.

Digital Print Vinyls

A printer which also serves as a plotter, will print out the artwork or logo on either Clear or White vinyl base. Clear vinyl base works well on light coloured or white fabrics while White vinyl base is used for dark coloured fabrics of t-shirts.

Weeding is also required to remove the vinyl material from the negative parts of the artwork or logo. As we do not want a big block of vinyl to be printed on the fabric, which would not feel comfortable for the wearer of the apparel.

Bleed area:

If the edges of a shape consists of many intricate details or there are small shapes in the artwork or logo, the digital print must have a bleed background around it that is of a similar colour to the fabrics. Using a bleed background will serve as a bounding area for the intricate details, allowing it to be printed and plotted.

The cutting line of the overall shapes of each print out must not be complicated or too detailed as the cutting done by the printer might become messy.

The diagram below shows what an ideal cutting line and a bleed background is like.

In some cases, an artwork or logo may require both Single Colour and Digital Print vinyls to be used for t-shirt printing. This will require an additional step in the heat press printing process. The vinyls will need to be pieced together with care to ensure no overlapping areas and must be well positioned to prevent any mispositioned elements which will affect the end visual effect for t-shirt printing.

Each type of vinyls require different durations of being heat pressed. Some vinyls’ underlying plastic sheet can be peeled directly after being pressed, while its hot. However some vinyls’s underlying plastic sheet will need to be left to cool after being pressed before peeled off. Understanding the properties of each vinyl type is important to ensure no vinyl material and time is wasted during the heat press printing process. To ensure high quality heat press prints on t-shirts, it is critical that no folded edges of the vinyl or distorted vinyl is heat pressed unto apparel.

Send us a message and we will contact you soon!

[ninja_form id=3]